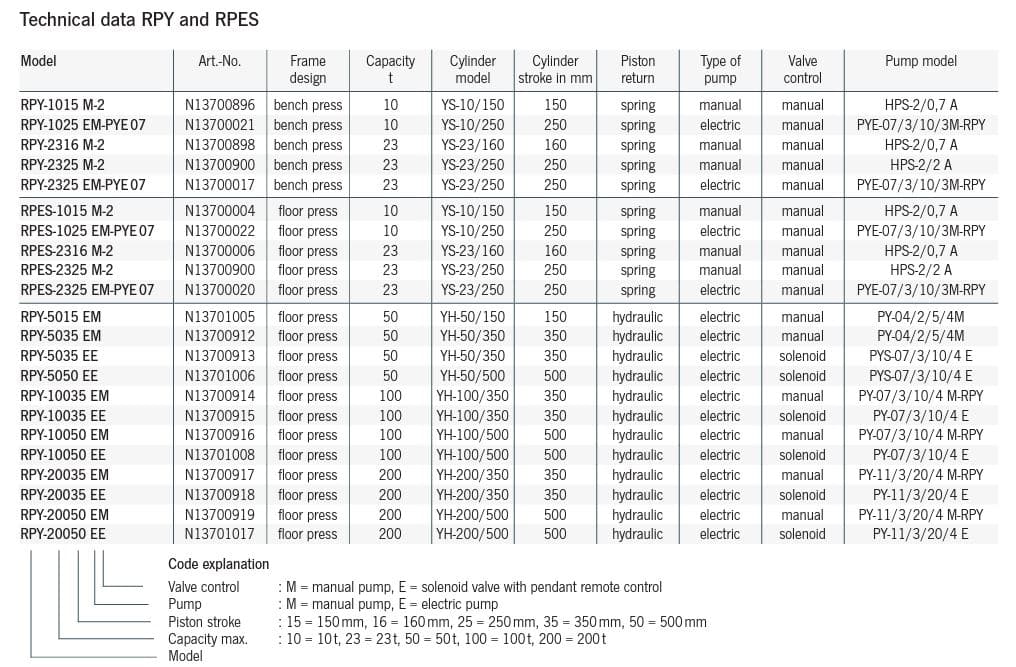

Description

For all repair and assembly jobs.

According to European standards, all Yale workshop presses can be used without any additional protection devices as the piston speed is below 10 mm/s.

For special applications additional safety equipment (e.g. protection grid or two-hand-safety-control) can be offered on request.

Applications

• Pressing and removing of bolts, shafts, bearings.

• Straightening of beams, profiles, axles, shafts.

• Forming, bending, crimping.

• General load tests and tests of weld specimens.

• Stamping, cutting, punching.

• Pre-adjustment of tools.

Equipment of all presses

Features

• All workshop presses are ready to use, including hydraulic oil, oil level gauge.

• High pressure-hydraulic hoses.

• Glycerine-damped pressure gauges.

• Fixing holes in base profiles, adjusting device for press table and head, swivelling pump console, conversion chart: Pressure-force etc.

Description of the hydraulic cylinders

Features

• Cylinders made from chromium-molybdenum steel, heat-treated and with metric mounting threads in the piston.

• Double bronze bearing of the hard chromium-plated piston.

• Piston return through spring or hydraulically.

• Mounting thread in the piston.

• Available piston strokes from 150 up to 500 mm.

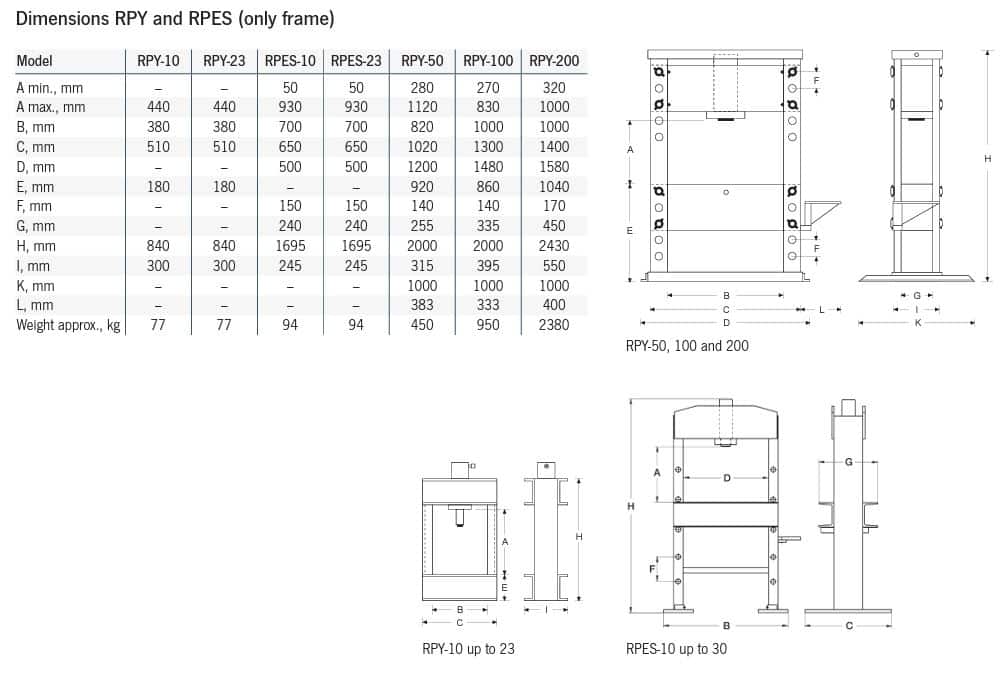

Description of the press-frame

Features

• Robust, torsion-resistant construction.

• Solid, precision-welded press-frames.

• Open construction, easily accessible from all sides.

• 50 and 100 tons workshop presses with adjustable press table and press head (frames for adjustments are part of the delivery package).

• 200 t press with adjustable table and fix welded press head.

• Four locking bolts ensure a precisely aligned press head and press table and increase the stability of the frame (50 and 100 t).

• 50, 100 and 200 t presses with pivoting pump table with peripheral passage for straigthening of exceptionaly long parts.

• Modular system: Large variety of combinations of hydraulic cylinders and pumps possible.

• Drive either by hand or electric hydraulic pumps.

Description of the hand pumps

Features

• All hand pumps with two-stage displacement.

• Glycerine-damped pressure gauge, Ø 63 mm, class 1.6 %..

• Hydraulic hose, L = 2.0 m with male coupler half.

Description of the hydraulic power packs

Features

• Longlife radial piston pumps, from 50 t with two-stage displacement.

• Pressure pre-set valve on request (standard equipment for the solenoid valves).

• Glycerine-damped pressure gauge, Ø 100 mm, class 1.0 %.

• Control by manual directional valve (with motor start-stop remote control) or solenoid valve with pendant remote control box.