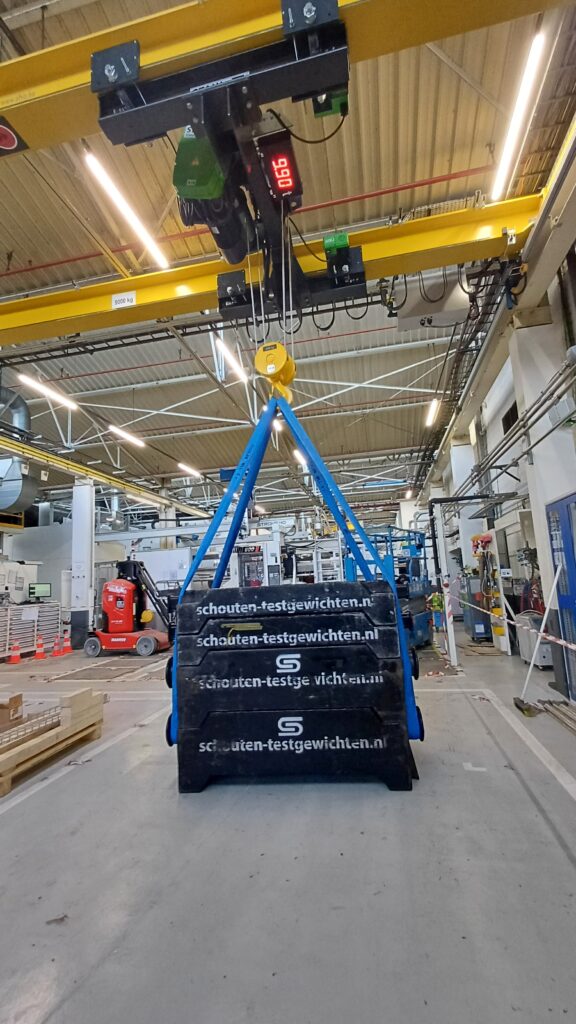

At OHIS, we are proud of our recent successful replacement of an overhead crane at a client specializing in the manufacturing of plastic components using injection molds. The existing overhead crane with a lifting capacity of 6.3 tons was no longer sufficient for replacing the molds of a new machine. The client required a lifting capacity of 9 tons, which posed a significant challenge given the limited space.

Our engineering team collaborated with the engineers from Stahl Cranesystems to devise an innovative solution. Instead of the existing 6.3-ton single girder, a 9-ton double girder was installed, with the hoist placed between the bridge beams. This allowed us to lift as high as possible without needing to replace the runway. The end carriages were enlarged to better distribute the reaction forces over the runway. Although the client had to compromise slightly on the approach dimension, this was not an issue.

To improve ease of use and safety, the new bridge is equipped with a digital load indicator and a wireless radio control. The biggest challenge, however, was installing the new overhead crane and removing the old one. Due to the limited space, we had to bring each part of the crane separately and assemble the crane at height on-site. Thanks to good preparation, teamwork, and the right tools, such as the Zallys electric tug, this task was completed safely and efficiently.

The client is extremely satisfied with the new installation, and we are proud of the result. This project once again demonstrates that OHIS is capable of providing innovative and effective solutions, even in the most challenging circumstances.